PI普爱 G-902.RxE运动控制器

PI普爱 G-902.RxE运动控制器

集成驱动器,最多可支持4个驱动轴,包括交流伺服电机、直流电机、音圈电机、步进

集成ACS驱动器和集成安全停止1(SS1)和安全扭矩关闭(STO)模块的ACS运动控制器

直接兼容PI的位置

用于交流伺服电机/无刷直流电机、有刷直流电机、音圈电机、步进电机

用于增量和绝对测量编码器的编码输入

每个轴的输出功率高达363瓦

多种轨迹规划选项

紧凑的19英寸机架安装外壳(2 HE) 经济的单元

输入/输出线

数字输入和输出可以灵活配置。对于参考开关的评估,数字输入可以替代性地引导到电机器。根据应用,极限和参考开关的输入可以配置为5 V或24 V,也可以作为PNP或NPN输入。位置同步触发,输出频率高达10 MHz,能够在高行程速度下实现精确的过程控制(位置事件发生器 – PEG)。

配置

如果在订时指定了使用的位置编码器类型,则G-902的所有连接器在交付时都会适当地预配置。默认的工厂配置,不进行编码器特定的调整,在规格中详细说明。对于后续调整,请联系我们的客户服务部门。

编码器

支持增量式编码器(正弦/余弦或RS-422),根据控制器型号,还支持式编码器(BiSS-C、EnDat 2.1 & 2.2、Smart-Abs、SSI、Sany-Denki、Panasonic A6)。根据应用情况,编码器可以分别连接到电机接口或独立的传感器接口。

通信,软件支持

与PC的通信,运动控制器配备了以太网TCP/IP和RS-232接口。ACSPii-Plus MMI应用工作室,一个现代用户软件,包含用于控制调优和可视化的工具,包含在交付范围内。C/C 、COM、.NET和MATLAB的编程库。

Specifications

|

|

G-902.R1E001 / G-902.R2E001 |

G-902.R1E002 |

|---|---|---|

|

Function |

ACS ECMsm controller with integrated servo controller |

|

|

Design |

19-inch rack-mount controller with connectors for positioners from PI |

|

|

Motor types |

2-phase and 3-phase AC servo motors / brushless DC motors, brushed DC motors, voice coil motors, stepper motors |

|

|

Number of drive axes |

4 |

2 |

|

Motion and Control |

G-902.R1E001 / G-902.R2E001 |

G-902.R1E002 |

|---|---|---|

|

Sample/Update rate of control loop |

20 kHz position 20 kHz velocity 20 kHz current |

|

|

Control algorithms |

Cascading PIVFF controller structure with loop-shaping filters Velocity feedforward MIMO (Multiple Input Multiple Output) gantry control algorithm Dual-loop control Disturbance rejection Gain scheduling Field-oriented control Space vector modulation |

|

|

Profile generation |

3rd order with uniform endpoint modification during operation |

|

|

Encoder |

1 × per integrated axis, supported types: Incremental: 1 Vpp, RS-422 Absolute: BiSS-C, EnDat 2.1 & 2.2, Smart-Abs, SSI, Sanyo-Denki, Panasonic A6 |

1 × per integrated axis, supported types: Incremental: 1 Vpp, RS-422 |

|

Limit switches |

2 × per integrated axis Default: 5 V sinking (NPN) Optional configuration: 24 V; sourcing (PNP) |

|

|

Reference switch |

Standard: 1 × per integrated axis, 5 V sinking (NPN) Optional configuration: 24 V; sourcing (PNP); use as digital multipurpose inputs on digital I/O connector (HD D-sub 15 (f)) |

|

|

Motor brake |

1 × per integrated axis Integrated PWM brake driver with current reduction for reduced brake heating |

|

|

Functional safety |

STO (safe torque off): Electrical interface: two-channel input, 24 V, insulated Safety standards: EN/IEC 61800-5-2 Ed. 2 (second environment) EN/IEC 61800-5-1 IEC 61508 IEC 62061 PLe performance level and category 3 according to: EN ISO 13849-1/-2 SS1 (safe stop 1): Braking time until STO activation: 110-230 ms The exact value for the braking time is a fixed value (SS1-t functionality) and depends on the product configuration. |

|

|

Electrical Properties |

G-902.R1E001 |

G-902.R2E001 |

G-902.R1E002 |

|---|---|---|---|

|

Intermediate circuit voltage |

48 V |

48 V |

48 V |

|

Output power intermediate circuit, continuous / peak (max. 10 s) |

550 W / 550 W at 40 °C |

1000 W / 1200 W at 40 °C |

550 W / 550 W at 40 °C |

|

Output power per axis (effective value), continuous / peak (max. 1 s) |

186 W* / 363 W* |

186 W / 363 W |

186 W / 363 W* |

|

Current limitation per motor phase (sine amplitude), continuous / peak (max. 1 s) |

5 A / 10 A |

5 A / 10 A |

5 A / 10 A |

|

Interfaces and Operation |

G-902.R1E001 / G-902.R2E001 |

G-902.R1E002 |

|---|---|---|

|

Motor connector** |

4 × HD D-sub 26 (f) |

2 × HD D-sub 26 (f) |

|

Sensor connector** |

4 × HD D-sub 26 (f) or via the motor connectors Connector selection per axis via DIP switch |

2 × HD D-sub 26 (f) or via the motor connectors Connector selection per axis via DIP switch |

|

Digital inputs |

Default: 4 × NPN 5 V sinking for reference switches on the motor and encoder connectors Optional configuration: Up to 4 multipurpose inputs, PNP 24 V source, parallel on 2 × HD D-sub 15 (f) |

|

|

Digital outputs |

2 × HD D-sub 15 (f): 4 × output PNP 24 V source; used for controlling the brake drivers D-sub 25 (f): 8 × multipurpose output, differential (RS-422) |

|

|

Analog inputs / outputs |

HD D-sub 15 (m): 2 differential analog inputs: ±10 V, 12 bit 2 differential analog outputs: ±10 V, 10 bit |

|

|

Outputs for position event generator (PEG) |

Parallel on HD D-sub 15 (m) and HD D-sub 15 (f): 4 differential outputs (RS-422) for pulses at programmable positions, pulse width 27 ns to 1.745 ms, max. 10 MHz; only possible with incremental encoder |

|

|

Inputs for STO safety function |

D-sub 9 (f): 2 inputs (STO1, STO2): 24 V, up to 50 mA per STO input, with an inrush current of less than 70 mA |

|

|

LEDs |

Status of the fuses for the 24 V power supply, STO signals, logic supply |

|

|

Cycle time of the controller |

1 kHz |

|

|

Communication interfaces |

Ethernet (TCP/IP, Ethernet/IP, Modbus/TCP): RJ-45 RS-232: D-sub 9 (m) |

|

|

User software |

ACS SPiiPlus MMI Application Studio |

|

|

Application programming interfaces |

Programming libraries for C/C++, COM, .NET, MATLAB available |

|

|

Programming |

ACSPL+ real-time script language: up to 6 simultaneously running programs (buffers) |

|

|

Miscellaneous |

G-902.R1E001 / G-902.R2E001 / G-902.R1E002 |

|---|---|

|

Operating voltage |

100-240 V AC, 50-60 Hz |

|

Required fusing per mains supply line |

IEC: 12-16 A at 250 V AC; 50 Hz UL/CSA: 12-20 A at 125/250 V AC; 60 Hz |

|

Operating temperature range |

5 to 40 °C (temperature protection switches off at excessively high temperatures) |

|

Mass |

10 kg |

|

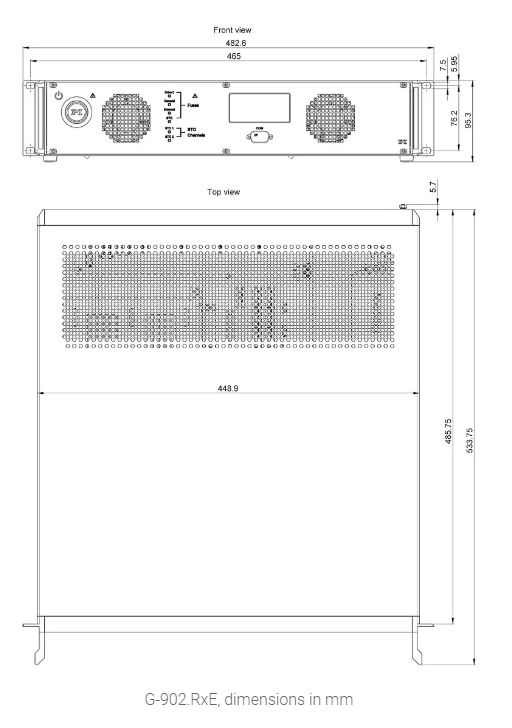

Dimensions |

482.6 mm × 533.75 mm × 95.3 mm (including handles) |

* 所有轴无法同时供电。

** G-902.R1E002: 2和3轴的电机和传感器连接器可用,但功能有限。

手机/微信:13242449659电话:0755-89355351 QQ:842471885 邮箱:842471885@qq.com